Understanding the Role of Siding Installers in Home Construction Projects: Materials, Tasks, Tools, Terms, and What to Expect

Siding is a critical component of any home’s exterior, providing protection from the elements, enhancing Energy Efficiency, and contributing to the overall aesthetic appeal of the property. Siding installers are specialized professionals who ensure that siding is properly installed, durable, and visually appealing.

This article provides a comprehensive overview of the materials, tasks, tools, and terminology associated with siding installation, as well as what homeowners can expect when working with siding installers on their construction project.

1. Materials Used by Siding Installers

Siding installers work with a variety of materials, each offering different benefits in terms of durability, maintenance, cost, and appearance. Common siding materials include:

Vinyl Siding: Vinyl is one of the most popular siding materials due to its affordability, low maintenance, and durability. It is available in a wide range of colors and styles, including Clapboard, shingles, and vertical panels. Vinyl siding is also resistant to moisture, rot, and insects.

Wood Siding: Wood siding offers a natural and classic look, with options such as Cedar, Pine, and redwood. It can be installed as clapboard, shingles, or board-and-Batten. While wood siding requires regular maintenance to protect against moisture and pests, it provides a warm, traditional aesthetic.

Fiber Cement Siding: Fiber Cement siding is made from a mixture of cement, sand, and cellulose fibers. It is known for its durability, resistance to fire, and ability to mimic the appearance of wood, Stucco, or Masonry. Fiber cement is low maintenance and can be painted in various colors.

Aluminum Siding: Aluminum siding is lightweight, durable, and resistant to rust and corrosion. It is often used for its low maintenance requirements and ability to withstand harsh weather conditions. Aluminum siding can be painted and is available in various styles, including smooth and textured finishes.

Engineered Wood Siding: Engineered Wood siding is made from wood fibers and resins, offering the appearance of natural wood with improved durability and resistance to moisture and pests. It is available in a variety of textures and styles and is generally more affordable than solid wood siding.

Stucco Siding: Stucco is a traditional siding material made from a mixture of cement, sand, and water. It is applied in multiple layers over a Wire Mesh and provides a durable, textured finish. Stucco is particularly popular in southwestern and Mediterranean-style homes.

Stone Veneer Siding: Stone veneer is a lightweight, manufactured product that mimics the appearance of Natural Stone. It is used to create a high-end, textured look without the weight and cost of real stone. Stone veneer can be applied to the entire exterior or used as an accent.

Brick Veneer Siding: Similar to stone veneer, brick veneer is a thin layer of brick that is applied to the exterior of a home. It offers the classic appearance of brick construction without the structural requirements of full brick walls. Brick veneer is durable, low maintenance, and provides excellent insulation.

2. Tasks Performed by Siding Installers

Siding installers perform a variety of tasks to ensure that the siding is properly installed, weatherproof, and visually appealing. Key tasks include:

Site Assessment and Preparation: The first step in siding installation is assessing the existing structure and preparing the site. The installer will inspect the home’s exterior for any damage, rot, or Mold that needs to be repaired before installing new siding. They may also remove existing siding or other materials to create a clean surface for installation.

Measurement and Layout: Accurate measurements are essential for ensuring that siding is properly aligned and that materials are used efficiently. The installer will measure the height and width of each wall, as well as the location of windows, doors, and other openings. This information is used to plan the layout and cutting of the siding panels.

Flashing and Moisture Barrier Installation: Before installing the siding, the installer will apply a moisture barrier, such as House Wrap or felt paper, to the exterior walls. This barrier helps prevent water from penetrating the walls and causing damage. Flashing is also installed around windows, doors, and other openings to direct water away from the structure.

Siding Installation: The installer attaches the siding panels to the exterior walls using Nails, Screws, or clips, depending on the material. They ensure that the panels are properly aligned, level, and overlapped to prevent water infiltration. For materials like vinyl or aluminum, expansion gaps may be left to accommodate temperature changes.

Trimming and Finishing: Once the main siding panels are installed, the installer will add Trim around windows, doors, corners, and Eaves. This trim not only enhances the appearance of the siding but also seals gaps and protects the edges from moisture. The installer may also apply Caulking around the trim to create a watertight seal.

Painting and Sealing: For certain siding materials, such as wood or fiber cement, the installer may need to paint or seal the siding after installation. This step protects the material from moisture, UV rays, and other environmental factors while allowing the homeowner to customize the color and finish.

Cleaning and Final Inspection: After the siding installation is complete, the installer will clean up the work area, removing any debris, nails, or leftover materials. They will conduct a final inspection to ensure that the siding is properly installed, secure, and free of defects. The homeowner may also be given maintenance instructions for the specific type of siding used.

3. Tools and Equipment Used by Siding Installers

Siding installers use a variety of specialized tools and equipment to perform their tasks efficiently and accurately. Common tools include:

Circular Saws and Miter Saws: Power saws used to cut siding panels, trim, and other materials to size. Circular saws are versatile for straight cuts, while miter saws are used for precise angle cuts, especially for trim work.

Nail Guns and Staplers: Pneumatic tools used to fasten siding panels and trim to the exterior walls. Nail guns are particularly useful for quickly and securely attaching siding materials like vinyl, wood, and fiber cement.

Levels and Measuring Tapes: Essential tools for ensuring that siding panels are installed level and properly aligned. Accurate measurements are crucial for maintaining a consistent appearance and preventing gaps or overlaps.

Utility Knives and Snips: Hand tools used for cutting and trimming siding materials, particularly for making adjustments around windows, doors, and other openings. Snips are commonly used for cutting metal siding, while utility knives are ideal for vinyl and other softer materials.

Caulking Guns: Tools used to apply Caulk around windows, doors, and other joints to create a watertight seal. Caulking guns are essential for preventing moisture infiltration and ensuring a long-lasting installation.

Scaffolding and Ladders: Equipment used to safely access higher areas of the home, such as the upper walls and eaves. Scaffolding provides a stable platform for working on tall structures, while ladders are used for smaller jobs and quick access.

Siding Removal Tools: Tools like pry bars and siding removal tools are used to carefully remove existing siding without damaging the underlying structure. This is especially important when replacing old siding or repairing sections of the exterior.

Power Drills and Impact Drivers: Cordless power tools used to drive screws and Fasteners into the siding and trim. These tools are essential for securing materials and ensuring that they are properly attached to the walls.

Vinyl Siding Removal Tools: Specialized tools designed to remove or adjust vinyl siding panels without damaging them. These tools are used to unlock panels that need to be repositioned or replaced.

4. Common Terms Used by Siding Installers

Understanding the terminology used by siding installers can help homeowners communicate more effectively and understand the processes involved in their project. Common terms include:

Clapboard: A type of siding made of long, narrow boards that are installed horizontally, with each board overlapping the one below it. Clapboard is commonly used in wood and vinyl siding.

Board-and-Batten: A siding style where wide vertical boards are installed with narrower strips (battens) covering the seams between the boards. This style is often used for a rustic or farmhouse look.

House Wrap: A moisture barrier material installed between the Sheathing and the siding to prevent water infiltration. House wrap is typically made from a synthetic material that allows vapor to escape while blocking water.

Flashing: Thin metal or plastic strips installed around windows, doors, and other openings to prevent water from seeping into the structure. Flashing is essential for protecting vulnerable areas from moisture damage.

Weep Holes: Small openings in siding, particularly in brick or stone veneer, that allow moisture to escape from behind the siding. Weep holes help prevent water buildup and potential damage to the structure.

J-Channel: A trim piece used with vinyl siding to create a finished edge around windows, doors, and other openings. J-channel helps secure the siding and provides a clean appearance.

Corner Posts: Vertical trim pieces installed at the corners of a building to cover the edges of the siding and create a finished look. Corner posts also help protect the corners from damage.

Butt Joint: A type of joint where two pieces of siding meet end-to-end, typically sealed with caulk or covered with trim to prevent moisture infiltration.

R-Value: A measure of thermal resistance used to rate the insulation properties of materials. Siding with a higher R-value provides better insulation and energy efficiency.

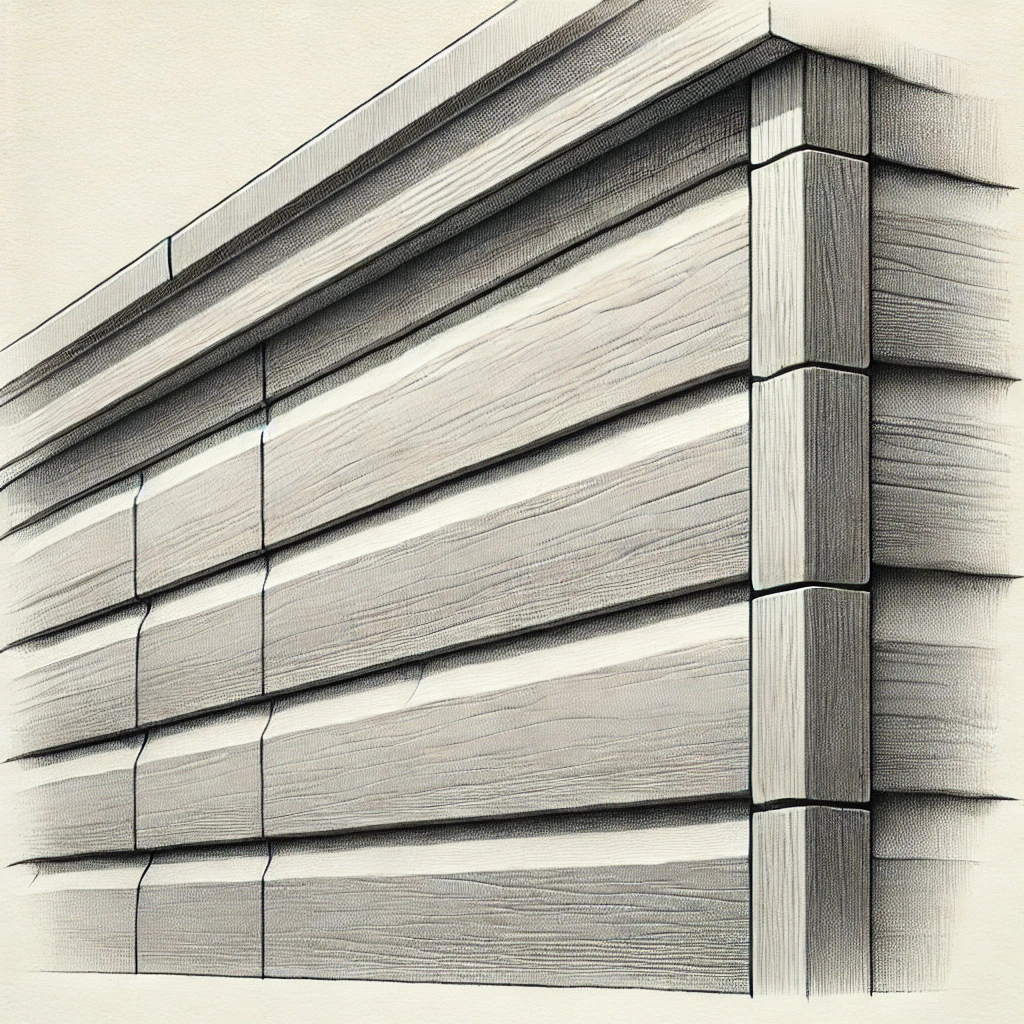

Lap Siding: A type of siding where each panel overlaps the one below it, creating a layered effect. Lap siding is commonly used in both horizontal and vertical installations.

5. What to Expect When Working with Siding Installers

When hiring a siding installer for your home construction project, there are several key expectations to keep in mind:

Initial Consultation and Assessment: The process begins with an initial consultation where the installer assesses the existing exterior, discusses your goals, and provides recommendations for siding materials, colors, and styles. They will also evaluate any potential issues, such as damage or moisture problems, that need to be addressed before installation.

Design and Proposal: After the assessment, the installer will create a detailed proposal that includes material options, labor costs, and a timeline for the project. This proposal will also outline the Scope of Work, including any necessary repairs or preparation work.

Permitting and Scheduling: Depending on the scope of the project, permits may be required for siding installation. The installer will help obtain the necessary permits and work with you to schedule the project at a convenient time.

Installation Process: The installation process includes site preparation, removal of existing siding (if necessary), installation of moisture barriers and flashing, and the application of the new siding. The installer will ensure that all materials are properly aligned, secured, and sealed to prevent water infiltration and damage.

Final Walkthrough and Inspection: Once the siding is installed, the installer will conduct a final walkthrough with you to ensure that the work meets your expectations. They will also provide maintenance tips and instructions for the specific type of siding used.

6. Examples of Siding Installers’ Work

a. Vinyl Siding Installation on a Suburban Home

A siding installer replaces the old wood siding on a suburban home with new vinyl siding, significantly improving the home's appearance and durability. The project includes installing a moisture barrier, flashing, and new trim around windows and doors. The result is a low-maintenance, weather-resistant exterior that enhances the home’s curb appeal.

b. Fiber Cement Siding on a Coastal Property

A coastal home requires siding that can withstand harsh weather conditions, including salt spray, high winds, and intense sun. The siding installer chooses fiber cement siding for its durability and ability to mimic the look of wood. The project includes custom painting and sealing to protect the siding from the elements while providing a stylish, modern look.

c. Stone Veneer Accent Siding on a Modern Home

A homeowner wants to add a high-end, textured look to their modern home. The siding installer adds stone veneer accents to the front façade, complementing the existing stucco siding. The project includes precise cutting and fitting of the stone veneer, as well as installing flashing and weep holes to manage moisture. The finished result adds a luxurious touch to the home's exterior.

7. Further Reading and Resources

For more information on siding materials, installation processes, and maintenance, consider visiting the following resources:

Vinyl Siding Institute: Vinyl Siding Institute Website

James Hardie - Fiber Cement Siding: James Hardie Website

National Association of Home Builders (NAHB): NAHB Website

These resources provide additional insights and can help you make informed decisions when planning and executing your siding installation project.

Wrap-Up

Siding installers play a crucial role in ensuring that your home’s exterior is not only visually appealing but also durable and weather-resistant. By understanding the materials, tasks, tools, and terms associated with siding installation, and knowing what to expect throughout the process, homeowners can ensure that their siding project is completed to the highest standards.

Whether you’re updating your home with new vinyl siding, adding stone veneer accents, or replacing old wood siding with durable fiber cement, working with skilled siding installers will help you achieve a beautiful, long-lasting exterior that enhances your home’s value and performance.