Understanding the Role of Flooring Installers in Home Construction Projects: Types of Floors, Materials, Tasks, Tools, Terms, and What to Expect

When undertaking a home construction or renovation project, one of the most important decisions you’ll make is choosing the right flooring. Flooring installers are the skilled professionals responsible for ensuring that your chosen flooring is installed correctly and beautifully.

This article provides a comprehensive guide to what you can expect when working with flooring installers, the different types of flooring materials they work with, the tasks they perform, the tools and equipment they use, common terms you’ll hear, and specific examples of their work.

1. Role and Responsibilities of Flooring Installers

Flooring Installers are professionals who specialize in laying various types of flooring materials, including Hardwood, Laminate, tile, Carpet, Vinyl, and more. Their expertise ensures that your flooring is installed correctly, adheres to manufacturer guidelines, and meets your aesthetic and functional needs.

Responsibilities Include:

Surface Preparation: Ensuring that the Subfloor is clean, level, and free of any defects before installing the flooring material.

Flooring Installation: Measuring, cutting, and fitting flooring materials to the exact dimensions of the room, and securing them in place according to the material’s specific installation requirements.

Finishing and Sealing: Applying finishes, stains, or sealants to protect the flooring material and enhance its appearance.

Repairs and Maintenance: Addressing any issues with existing flooring, such as replacing damaged sections or refinishing surfaces.

2. Types of Flooring Materials

Flooring installers work with a wide range of materials, each offering different benefits, aesthetics, and installation methods. Here are some common types of flooring materials you might consider for your project:

a. Hardwood Flooring

Description: Hardwood flooring is made from solid wood Planks, typically oak, Maple, or cherry. It’s known for its durability, timeless beauty, and ability to be sanded and refinished multiple times.

Example: A homeowner chooses oak hardwood flooring for their living room, appreciating its natural Grain and the warmth it adds to the space. The flooring installer carefully lays each plank, ensuring a snug fit and a smooth surface.

b. Engineered Wood Flooring

Description: Engineered wood flooring consists of a real Wood Veneer on top of multiple layers of Plywood or high-density fiberboard (HDF). It offers the look of hardwood with greater resistance to moisture and temperature changes.

Example: In a basement renovation, the homeowner selects engineered wood flooring due to its stability in areas with higher humidity. The flooring installer uses a click-lock system to install the planks, ensuring a tight, secure fit.

c. Laminate Flooring

Description: Laminate flooring is made of a synthetic material that simulates the look of wood, stone, or tile. It’s known for its affordability, durability, and ease of installation.

Example: The homeowner installs laminate flooring in the kitchen, choosing a design that mimics the appearance of stone tiles. The flooring installer uses a floating installation method, where the planks are not glued or nailed but instead clicked together and laid over an underlayment.

d. Tile Flooring

Description: Tile flooring can be made from ceramic, porcelain, or Natural Stone. It’s highly durable, water-resistant, and available in a wide variety of colors, patterns, and sizes.

Example: The homeowner selects Porcelain Tile for their bathroom, appreciating its water resistance and modern look. The flooring installer carefully lays the tiles with precision, ensuring even spacing and applying Grout to seal the joints.

e. Vinyl Flooring

Description: Vinyl flooring, including luxury vinyl plank (LVP) and Luxury Vinyl Tile (LVT), is a synthetic material that offers water resistance, durability, and a wide range of styles. It can mimic the appearance of wood, stone, or tile.

Example: In a laundry room, the homeowner chooses LVP flooring for its water resistance and easy maintenance. The flooring installer cuts the planks to fit around appliances and fixtures, then uses an adhesive to secure them to the subfloor.

f. Carpet Flooring

Description: Carpet is a soft flooring material made from natural or synthetic fibers. It’s known for its comfort, warmth, and sound-dampening properties. Carpets come in various textures, colors, and pile heights.

Example: The homeowner opts for plush carpeting in the bedrooms, valuing its softness and warmth underfoot. The flooring installer stretches the carpet over a pad, securing it with tack strips along the edges of the room.

g. Cork Flooring

Description: Cork flooring is made from the bark of the cork oak tree and is known for its eco-friendliness, comfort, and sound insulation properties. It’s also naturally resistant to Mold, mildew, and pests.

Example: The homeowner selects cork flooring for a home office, appreciating its softness and Thermal Insulation. The flooring installer glues the cork tiles to the subfloor, creating a seamless, cushioned surface.

h. Bamboo Flooring

Description: Bamboo flooring is a sustainable material made from the bamboo plant. It’s durable, environmentally friendly, and offers a unique, natural appearance.

Example: In a modern living room, the homeowner chooses bamboo flooring for its eco-friendliness and sleek look. The flooring installer uses a nail-down method to secure the bamboo planks to the subfloor, ensuring a stable installation.

3. Common Flooring Tasks Performed by Installers

Flooring installers perform a variety of tasks to ensure your flooring is installed correctly and meets your expectations. Here are some common tasks you can expect:

a. Subfloor Preparation

Description: The subfloor must be properly prepared before any flooring material is installed. This includes cleaning, Leveling, and repairing any defects to ensure a smooth, stable surface.

Example: Before installing hardwood flooring, the installer checks the subfloor for any uneven areas and uses a Leveling Compound to create a flat, stable base.

b. Flooring Measurement and Layout

Description: Accurate measurement and layout are crucial to ensuring that the flooring fits correctly and looks visually appealing. This task involves measuring the room, planning the layout, and cutting materials to size.

Example: For a tile floor installation, the installer carefully measures the room and plans the tile layout to ensure that the tiles are evenly spaced and the pattern is centered in the room.

c. Installation of Underlayment

Description: Underlayment is a layer of material placed between the subfloor and the flooring material. It provides additional cushioning, sound insulation, and moisture protection, depending on the type of flooring.

Example: The installer lays down a foam underlayment before installing laminate flooring in a basement, providing a Moisture Barrier and cushioning underfoot.

d. Flooring Installation

Description: The primary task of a flooring installer is to lay the flooring material according to the manufacturer’s guidelines. This involves cutting, fitting, and securing the material to the subfloor.

Example: During a hardwood floor installation, the installer carefully lays each plank, securing them with nails or staples to ensure a tight fit and a smooth surface.

e. Finishing and Sealing

Description: Depending on the type of flooring, the installer may apply finishes, stains, or sealants to protect the material and enhance its appearance. This task is especially common with hardwood and tile floors.

Example: After installing a tile floor, the installer applies grout to the joints between the tiles and seals the grout to prevent staining and moisture penetration.

f. Repair and Maintenance

Description: Flooring installers also perform repair and maintenance tasks, such as replacing damaged sections, refinishing hardwood floors, or re-stretching carpet to remove wrinkles.

Example: The homeowner notices a few scratches on their hardwood floor. The installer sands and refinishes the affected area, restoring the floor to its original appearance.

4. Tools and Equipment Used by Flooring Installers

Flooring installers use a variety of specialized tools and equipment to complete their work efficiently and accurately. Here are some of the most common tools and what they’re used for:

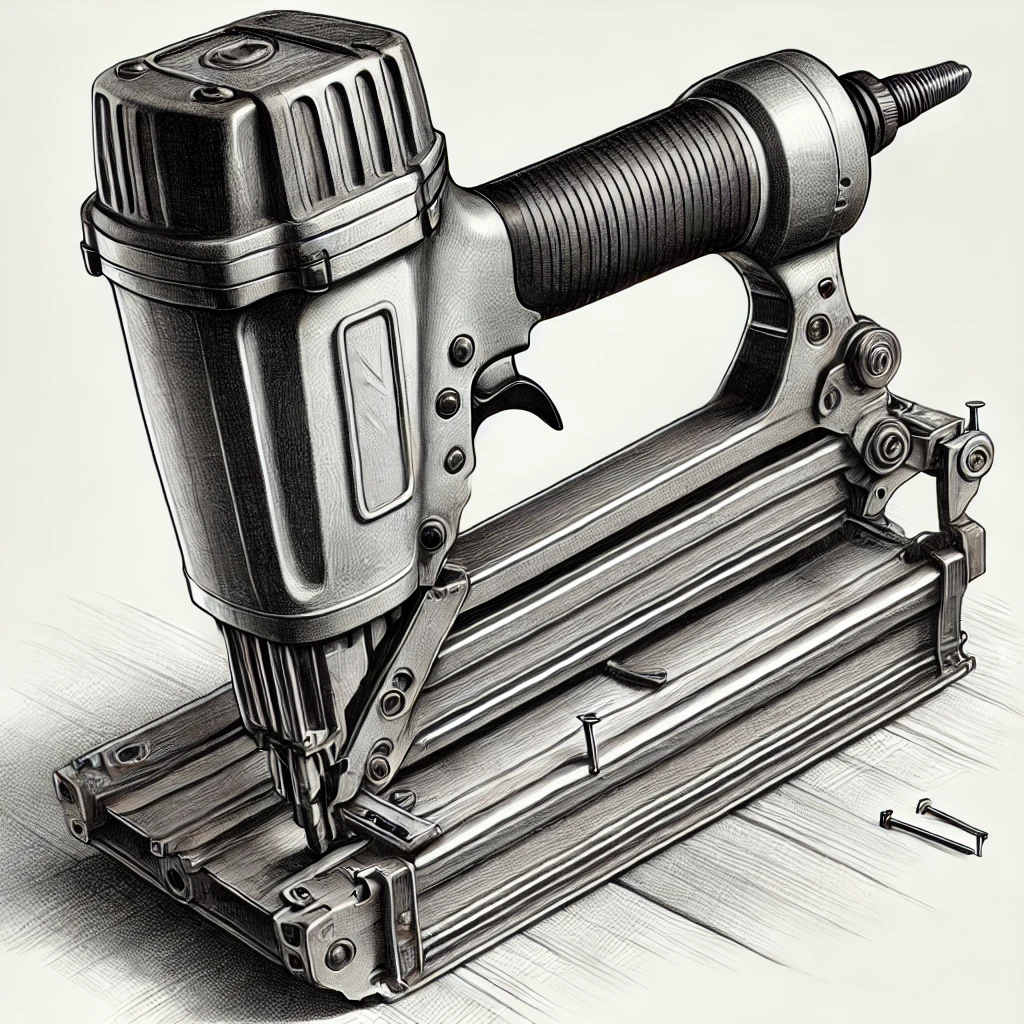

a. Flooring Nailer/Stapler

Purpose: A flooring nailer or stapler is used to secure hardwood or Engineered Wood planks to the subfloor. This tool ensures that each plank is tightly fastened and prevents shifting.

Example: The installer uses a pneumatic flooring nailer to secure oak hardwood planks during installation, ensuring a tight fit and reducing the risk of gaps between the boards.

b. Tile Cutter/Wet Saw

Purpose: A tile cutter or wet saw is used to cut ceramic, porcelain, or stone tiles to the correct size and shape. Wet saws use water to cool the blade and reduce dust while cutting.

Example: The installer uses a wet saw to cut tiles around the edges of a bathroom floor, ensuring a precise fit around fixtures and walls.

c. Carpet Stretcher

Purpose: A carpet stretcher is a tool used to stretch carpet across a room and secure it to tack strips along the edges. It ensures that the carpet lies flat and free of wrinkles.

Example: The installer uses a power stretcher to pull the carpet taut across a living room, preventing wrinkles and ensuring a smooth, even surface.

d. Jamb Saw

Purpose: A jamb saw is used to cut door jambs and Trim to allow flooring material, such as hardwood or tile, to fit neatly underneath. This tool ensures a clean, professional finish around doorways.

Example: The installer uses a jamb saw to trim the door casings before installing tile in the entryway, allowing the tiles to slide under the door Frame for a seamless look.

e. Tapping Block and Pull Bar

Purpose: Tapping blocks and pull bars are used during the installation of floating floors, such as laminate or vinyl planks. They help snug the planks together without damaging the edges.

Example: The installer uses a tapping block and pull bar to secure the seams between laminate planks in a kitchen, ensuring a tight fit and reducing the appearance of gaps.

f. Floor Scraper

Purpose: A floor scraper is used to remove old adhesive, paint, or debris from the subfloor before new flooring is installed. It ensures a clean surface for proper adhesion.

Example: The installer uses a floor scraper to remove old adhesive from the subfloor after removing vinyl flooring, preparing the surface for the installation of new tile.

5. Common Terms Used by Flooring Installers

Understanding the terminology used by flooring installers can help you communicate more effectively and make informed decisions. Here are some common terms you’ll hear:

a. Subfloor

Definition: The subfloor is the structural layer beneath the finished floor. It provides support and stability for the flooring material. Subfloors are typically made of plywood, Concrete, or oriented strand board (OSB).

Example: The installer checks the subfloor for any damage or uneven areas before installing new hardwood flooring, ensuring a stable Foundation.

b. Underlayment

Definition: Underlayment is a material placed between the subfloor and the finished flooring to provide cushioning, sound insulation, and moisture protection. Different types of underlayment are used depending on the flooring material.

Example: The installer lays a cork underlayment beneath the bamboo flooring in the living room to provide sound insulation and additional comfort underfoot.

c. Floating Floor

Definition: A floating floor is a type of flooring installation where the planks or tiles are not glued or nailed to the subfloor but are instead connected to each other and "float" over an underlayment.

Example: The installer uses a click-lock system to install laminate flooring as a floating floor, allowing for easy installation and the ability to expand and contract with temperature changes.

d. Grout

Definition: Grout is a cement-based material used to fill the joints between tiles. It helps secure the tiles in place and provides a finished appearance. Grout can be sealed to protect it from stains and moisture.

Example: After laying ceramic tiles in the bathroom, the installer applies grout between the tiles and then seals the grout to prevent moisture penetration and staining.

e. Expansion Gap

Definition: An expansion gap is a small space left between the flooring material and the walls or other fixed objects. This gap allows the flooring to expand and contract with temperature and humidity changes without causing buckling or warping.

Example: The installer leaves a 1/4-inch expansion gap around the perimeter of the laminate floor in the basement, covering it with Baseboard trim to allow for seasonal movement.

f. Transition Strip

Definition: A transition strip is a piece of molding used to cover the seam where two different types of flooring meet, such as where hardwood meets tile or carpet. It provides a smooth transition between rooms and prevents tripping hazards.

Example: The installer uses a T-Molding transition strip to create a smooth transition between the hardwood floor in the living room and the tile floor in the kitchen.

6. What to Expect When Working with Flooring Installers

When you hire flooring installers for your home construction project, you can expect a process that involves careful planning, precise execution, and attention to detail. Here’s what you should anticipate:

a. Initial Consultation and Material Selection

The process typically begins with an initial consultation where the flooring installer will discuss your project, assess the space, and help you choose the best flooring material for your needs and budget. They will also provide an estimate for the installation.

Example: The homeowner meets with the installer to discuss options for replacing the carpet in the bedrooms with hardwood flooring. The installer provides samples of different wood species and finishes, helping the homeowner select the best option.

b. Subfloor Preparation

Before the flooring material is installed, the subfloor must be prepared. This may involve cleaning, leveling, and repairing any defects to ensure a smooth, stable surface. The installer may also lay down an underlayment if required.

Example: The installer inspects the subfloor in a kitchen remodel and identifies a low spot. They use a leveling compound to create an even surface, ensuring that the new tile floor will be level and secure.

c. Flooring Installation

Once the subfloor is prepared, the installer will begin laying the flooring material according to the manufacturer’s guidelines. This involves cutting the material to fit, securing it in place, and ensuring a precise, even installation.

Example: During the installation of carpet in a bedroom, the installer stretches the carpet over a pad and secures it to tack strips around the room’s perimeter, ensuring a smooth, wrinkle-free finish.

d. Finishing Touches

After the flooring is installed, the installer will complete any necessary finishing touches, such as applying grout, sealing the surface, or installing baseboards and transition strips.

Example: After installing a hardwood floor in the living room, the installer applies a protective finish to enhance the wood’s natural beauty and protect it from wear.

e. Inspection and Clean-Up

Once the work is completed, the installer will conduct a Final Inspection to ensure that the flooring is installed correctly and meets your expectations. They will also clean up the work area, removing any debris or leftover materials.

Example: After completing a vinyl plank floor installation in the kitchen, the installer inspects the seams and edges to ensure they are properly aligned and tight. They then clean up any adhesive residue and sweep the floor.

7. Further Reading and Resources

For more information on working with flooring installers and understanding their role in construction projects, consider visiting the following resources:

National Wood Flooring Association (NWFA): NWFA Website

Tile Council of North America (TCNA): TCNA Website

World Floor Covering Association (WFCA): WFCA Website

Fine Homebuilding - Wood Flooring Installation Guide: Fine Homebuilding

The Spruce - Flooring Installation Basics: The Spruce

These resources can provide additional insights and help you make informed decisions when working with flooring installers on your home construction project.

Wrap-Up

Flooring installers play a crucial role in ensuring that your home’s floors are not only beautiful but also durable and functional. By understanding the different types of flooring materials, the tasks involved in installation, the tools and equipment they use, and what to expect during the process, you can ensure that your flooring project meets your expectations and enhances the overall value and comfort of your home.

Whether you’re installing new hardwood floors, updating your kitchen with tile, or replacing carpet in the bedrooms, working with skilled flooring installers is key to achieving a high-quality result that you’ll enjoy for years to come.