Understanding the Role of Metalworkers & Blacksmiths in Home Construction Projects: Materials, Tasks, Tools, Terms, and What to Expect

Metalworkers and blacksmiths play a vital role in home construction projects, bringing both functional and decorative elements to life through their mastery of metalwork. From creating sturdy structural components to crafting intricate decorative pieces, these skilled professionals add a unique touch to homes.

This article provides a detailed overview of the materials, tasks, tools, and terms associated with metalworkers and blacksmiths, as well as what homeowners can expect when working with them.

1. Materials Used by Metalworkers & Blacksmiths

Metalworkers and blacksmiths work with a variety of metals, each suited to different applications in construction and decorative projects. Common materials include:

Steel: Steel is widely used for structural elements due to its strength and durability. It’s also commonly used for gates, Railings, and furniture. It can be galvanized to prevent rust or left unfinished for a more rustic appearance.

Iron: Iron, particularly Wrought Iron, is often used in decorative metalwork. Wrought iron is known for its malleability, which allows blacksmiths to create intricate designs such as scrolls and floral patterns.

Aluminum: Aluminum is lightweight, corrosion-resistant, and easy to work with, making it ideal for outdoor furniture, fencing, and Decorative Panels. It is often used in projects where weight is a concern.

Copper: Copper is valued for its distinctive color and natural patina that develops over time. It’s commonly used for roofing, gutters, and decorative elements like finials and weather vanes.

Brass and Bronze: These copper alloys are prized for their aesthetic qualities and resistance to corrosion. They are often used for hardware, lighting fixtures, and ornamental details.

2. Tasks Performed by Metalworkers & Blacksmiths

Metalworkers and blacksmiths undertake a wide range of tasks in home construction projects, including both functional and decorative work. Key tasks include:

Fabrication: Metalworkers fabricate various components from raw materials, such as beams, columns, Brackets, and custom metal parts. This process involves cutting, bending, welding, and assembling metal pieces to meet the specific requirements of the project.

Forging: Blacksmiths use traditional forging techniques to shape metal by heating it in a forge and hammering it into the desired form. This task is typically used for creating custom ironwork, such as gates, railings, and decorative elements.

Welding: Welding is the process of joining metal pieces together by melting the edges and adding filler material. It is essential for creating strong, durable joints in structural and decorative metalwork.

Finishing: After fabrication and assembly, metal pieces often undergo finishing processes such as grinding, sanding, and polishing to achieve a smooth, refined surface. Finishing may also include applying coatings or paints to protect the metal from corrosion.

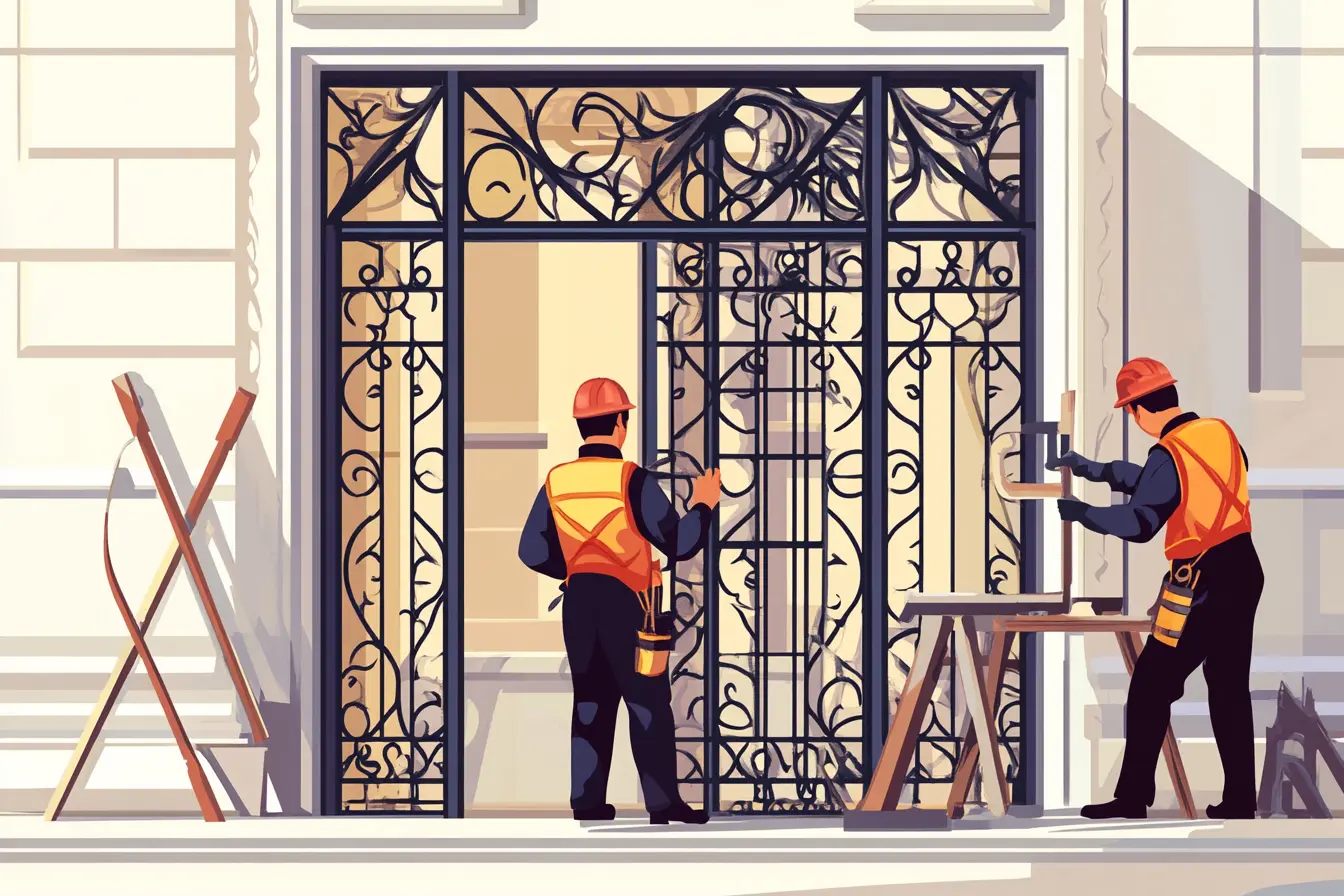

Installation: Metalworkers and blacksmiths are also responsible for installing the metal components they create. This can include everything from mounting railings and gates to installing metal roofs or structural elements.

3. Tools and Equipment Used by Metalworkers & Blacksmiths

Metalworkers and blacksmiths use a variety of specialized tools and equipment to carry out their tasks. Common tools include:

Forge: A forge is used to heat metal to high temperatures, making it malleable for shaping and forging. Blacksmiths often use coal, propane, or natural gas forges in their work.

Anvil: The anvil is a heavy, flat-topped tool used as a surface for hammering and shaping hot metal. It is a fundamental tool in blacksmithing.

Hammer: Various hammers are used in metalworking, including forging hammers, ball-peen hammers, and sledgehammers. Each type serves a specific purpose, from shaping metal to striking tools.

Welding Equipment: This includes welding machines (MIG, TIG, or arc welders), protective gear, and welding rods or wire. Welding equipment is essential for joining metal pieces together.

Grinders and Sanders: These tools are used to smooth and finish metal surfaces, removing any rough edges or imperfections. They are also used to prepare metal surfaces for painting or coating.

Cutting Tools: Metalworkers use cutting tools such as plasma cutters, oxy-acetylene torches, and metal saws to cut metal sheets, rods, and bars to size.

Bending Tools: Tools like metal brakes and rollers are used to bend and shape metal sheets and bars into desired forms.

4. Common Terms Used by Metalworkers & Blacksmiths

When working with metalworkers and blacksmiths, you may hear several industry-specific terms. Understanding these terms can help you communicate more effectively and understand the processes involved:

Patina: A surface finish that develops on metal, particularly copper and bronze, over time due to oxidation. Patina can be artificially induced to achieve a desired aesthetic.

Galvanization: The process of applying a protective zinc coating to steel or iron to prevent rusting. Galvanized metal is commonly used in outdoor applications.

Annealing: A heat treatment process used to soften metal, making it easier to work with and reducing the likelihood of cracking during shaping.

Quenching: Rapid cooling of hot metal, usually in water or oil, to harden it. Quenching is often used in blacksmithing to increase the strength of steel.

Tempering: A heat treatment process applied after quenching to reduce the brittleness of metal, improving its toughness and durability.

Wrought Iron: Iron that has been heated and then worked with tools to create a variety of shapes. Wrought iron is highly malleable and is often used for ornamental metalwork.

Casting: The process of pouring molten metal into a Mold to create a specific shape. Casting is commonly used to create complex metal parts and decorative elements.

5. What to Expect When Working with Metalworkers & Blacksmiths

When hiring metalworkers and blacksmiths for your home construction project, it’s important to understand what to expect throughout the process. Here are some key points:

Customization: Metalworkers and blacksmiths often create custom pieces tailored to your specific needs and preferences. This could include anything from custom railings and gates to unique furniture or architectural elements.

Collaboration: You’ll likely collaborate closely with the metalworker or blacksmith to develop designs and select materials that match your vision. This process may involve reviewing sketches, 3D models, or prototypes.

Lead Times: Custom metalwork often requires a significant amount of time for design, fabrication, and finishing. Be prepared for longer lead times, especially for complex or highly detailed projects.

Site Visits: Depending on the nature of the work, the metalworker or blacksmith may need to visit your home to take measurements, assess the site, or handle installation. This ensures that the finished product fits perfectly and functions as intended.

Durability: Metalwork is known for its durability and longevity. Properly maintained metal components can last for decades, making them a worthwhile investment in your home.

6. Examples of Metalworker & Blacksmith Projects

a. Custom Wrought Iron Gate

A homeowner commissions a blacksmith to create a custom wrought iron gate for their Driveway. The design features intricate scrollwork and a family crest. The blacksmith heats the iron in a forge, shapes it using hammers and an anvil, and then welds the pieces together. The gate is finished with a weather-resistant coating and installed on-site.

b. Steel Staircase Railing

A metalworker is hired to fabricate a modern steel railing for a staircase in a newly built home. The design calls for clean lines and a minimalist aesthetic. The metalworker cuts, welds, and polishes the steel components, ensuring precise alignment and a seamless finish. The railing is installed and secured to the staircase, providing both safety and style.

c. Copper Roofing

A homeowner chooses copper for their new roof, valuing its durability and the beautiful patina it will develop over time. The metalworker measures and cuts the copper sheets, then uses specialized tools to shape and fit them to the roof. The copper roofing is installed, providing a long-lasting, low-maintenance solution that enhances the home’s curb appeal.

7. Further Reading and Resources

For more information on working with metalworkers and blacksmiths, as well as understanding their role in construction projects, consider visiting the following resources:

Artist-Blacksmith's Association of North America (ABANA): ABANA Website

The Metalworking Group: The Metalworking Group Website

The Anvilfire Guru's Den: Anvilfire

These resources can provide additional insights and help you make informed decisions when working with metalworkers and blacksmiths on your home construction project.

Wrap-Up

Metalworkers and blacksmiths bring a unique blend of craftsmanship and artistry to home construction projects, creating durable and aesthetically pleasing metalwork that can enhance the overall value and appeal of your home. By understanding the materials, tasks, tools, and terms associated with their work, and knowing what to expect during the process, you can ensure that your metalwork project meets your expectations and adds a distinctive touch to your home. Whether you’re commissioning a custom wrought iron gate, installing a steel staircase railing, or opting for copper roofing, working with skilled metalworkers and blacksmiths is key to achieving a high-quality result that will stand the test of time.