A Homeowner’s Guide to Working with Furniture Makers: Crafting Custom Pieces for Your Home

Furniture makers bring artistry and craftsmanship to the spaces we live in, creating bespoke pieces that are tailored to your style and functional needs. Unlike mass-produced furniture, custom pieces made by furniture makers are designed to last, often becoming cherished heirlooms that add character to your home.

This article will help you understand the role of furniture makers, the materials they use, common tasks, tools, and techniques, and what to expect when working with them.

Understanding Furniture Makers

Furniture Makers are skilled artisans who design, build, and finish custom furniture pieces using wood, metal, and other materials. Their work ranges from creating one-of-a-kind dining tables and chairs to intricate Built-in cabinetry and storage solutions. Furniture makers often collaborate with interior designers, architects, and homeowners to craft pieces that fit seamlessly into a specific design vision, providing a personalized touch that cannot be replicated by off-the-shelf options.

Types of Materials Used by Furniture Makers

Hardwoods: Such as oak, walnut, cherry, and Maple, are popular choices for furniture making due to their durability and attractive Grain patterns. Hardwoods are often used for high-quality furniture like dining tables, chairs, and cabinets.

Softwoods: Including Pine, Cedar, and fir, are easier to work with and are often used in rustic or casual furniture styles. They are commonly used in less formal furniture, built-ins, or painted pieces.

Plywood: An Engineered Wood made from layers of Veneer glued together, plywood is strong and stable, making it ideal for cabinetry, shelves, and other large surfaces where solid wood might warp.

Veneers: Thin slices of wood applied over a base material like MDF (Medium-Density Fiberboard) or plywood to give the appearance of solid wood. Veneers are used to create a high-end look without the cost or weight of solid wood.

Metal (Steel, Brass, Aluminum): Furniture makers incorporate metals into their designs for frames, legs, and decorative accents. Metals can add a modern or industrial touch to furniture.

Upholstery Fabrics and Leathers: For seating, headboards, and other cushioned items, furniture makers use various fabrics, including leather, velvet, and performance Textiles that are durable and stylish.

Common Tasks of Furniture Makers

Custom Design and Sketching: Furniture makers work closely with clients to understand their needs, preferences, and the space where the piece will be placed. They often start with sketches or 3D models to visualize the final design.

Joinery: A key aspect of woodworking, joinery involves techniques for connecting pieces of wood without the need for Nails or Screws. Common joinery methods include dovetail, mortise and tenon, and Tongue and Groove, which provide strength and add a decorative element.

Woodworking and Shaping: Cutting, planing, and sanding wood to create the desired shapes and forms. This process includes working with hand tools and machinery to achieve precise measurements and smooth finishes.

Finishing: Applying stains, paints, varnishes, or waxes to protect the wood and enhance its appearance. The finishing process can drastically change the look of a piece, from highlighting the natural grain to creating a sleek, modern surface.

Upholstery: For furniture that includes padded elements, such as sofas or chairs, furniture makers work with upholsterers or handle the upholstery process themselves, choosing fabrics that complement the overall design.

Common Tools and Equipment

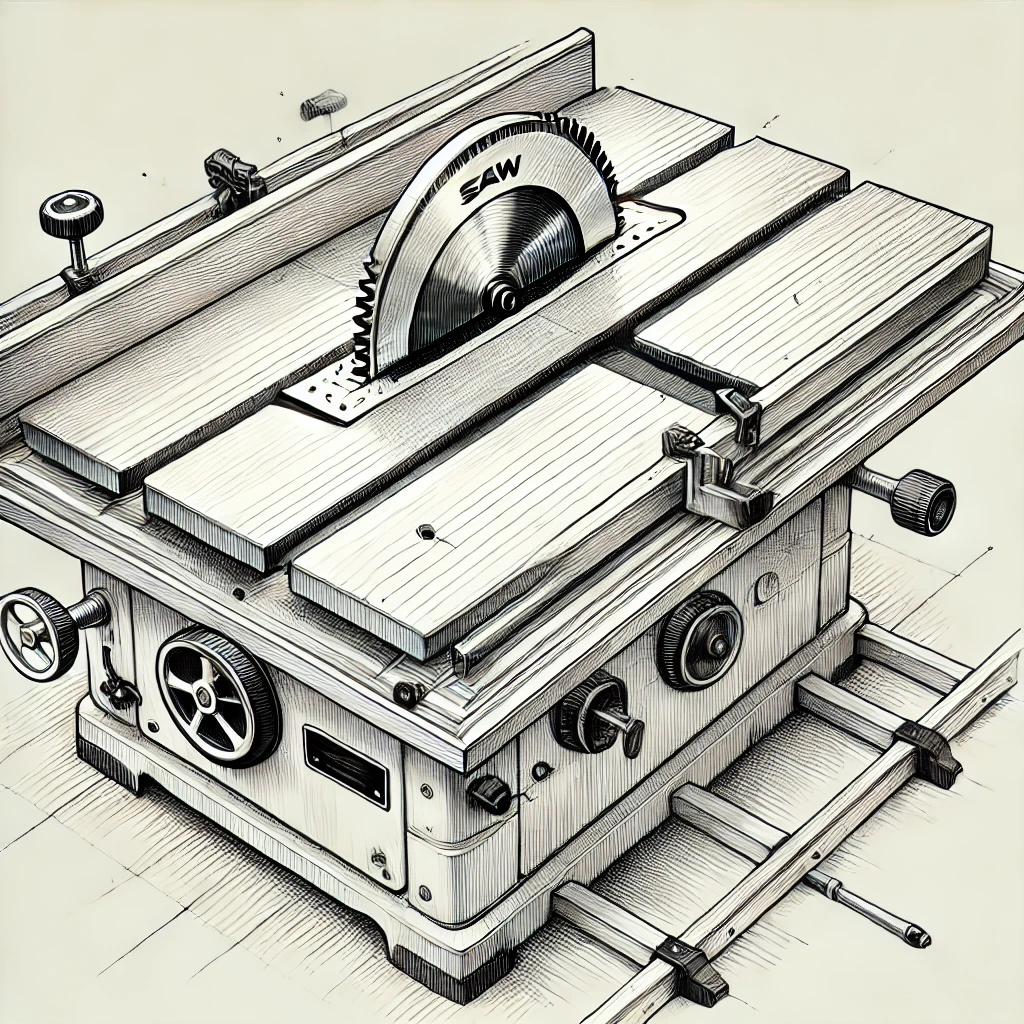

Table Saw: Essential for cutting wood to precise sizes, the table saw is the backbone of most woodworking shops.

Router: A versatile tool used to create decorative edges, grooves, and joinery details.

Planer and Jointer: Used to flatten and smooth wood surfaces, ensuring that all pieces fit together perfectly during assembly.

Chisels: Hand tools used for carving and shaping wood, especially for detailed joinery work.

Clamps: Necessary for holding pieces of wood together while the glue sets during assembly.

Sanders: Electric or hand tools used to smooth wood surfaces before finishing.

Spray Gun or Brush: Used to apply stains, varnishes, or paints evenly, creating a professional-quality finish.

Terms You Might Hear

Live Edge: A style where the natural edge of the wood is preserved, adding a rustic and organic feel to furniture like tables and benches.

Patina: The natural aging of wood, often desirable in antique or reclaimed furniture, giving it character and a sense of history.

Mortise and Tenon: A traditional woodworking joint where a protruding tenon fits into a mortise hole, creating a strong and aesthetically pleasing connection.

Grain: The natural pattern of wood fibers, which can be enhanced through careful selection and finishing to highlight the wood’s beauty.

Reclaimed Wood: Wood salvaged from old buildings or furniture, valued for its weathered appearance and Sustainability.

Kiln-Dried: Wood that has been dried in a kiln to remove moisture, making it less prone to warping and cracking.

What to Expect

1. Initial Consultation:

The furniture maker will meet with you to discuss your needs, preferences, and the intended use of the furniture piece. They may take measurements of the space where the piece will go and discuss design styles, wood types, and finishes.

During this stage, you will review initial sketches or mood boards that help visualize the design concept.

2. Design and Approval:

After the initial consultation, the furniture maker will refine the design, often providing detailed drawings or 3D renderings. This step allows you to see the exact proportions, materials, and finishes before construction begins.

Once the design is approved, the maker will source the materials and start the fabrication process.

3. Fabrication:

The furniture maker cuts, shapes, and assembles the wood, often employing traditional joinery techniques for strength and beauty. For complex designs, this phase can involve multiple steps, including carving, turning, or bending wood into unique forms.

If the piece includes upholstery, the furniture maker will coordinate with a seamster or upholsterer to select fabrics and apply them to the furniture.

4. Finishing and Delivery:

Once the piece is assembled, the finishing process begins. This involves sanding the wood, applying stains or paints, and adding protective coatings to ensure the piece is both beautiful and durable.

After finishing, the furniture is delivered to your home, where the maker may provide final assembly or installation, ensuring the piece fits perfectly in its intended space.

Examples

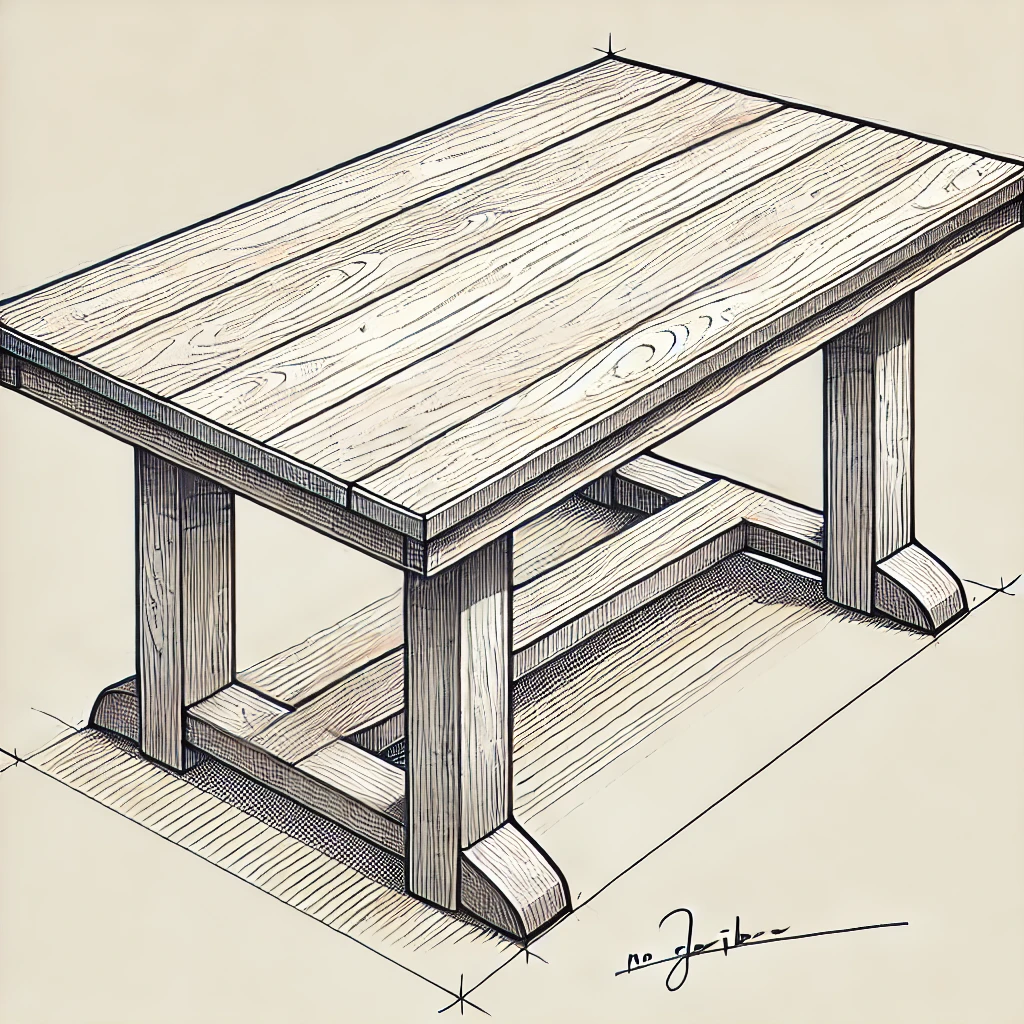

Example 1: Custom Dining Table for a Modern Home

A homeowner desires a unique dining table that fits their modern aesthetic. After a detailed consultation, the furniture maker designs a sleek, rectangular table with a live-edge walnut top and steel legs. The table is custom-sized to fit the dining room and finished with a natural oil to enhance the wood grain. The result is a stunning centerpiece that blends warmth and contemporary style.

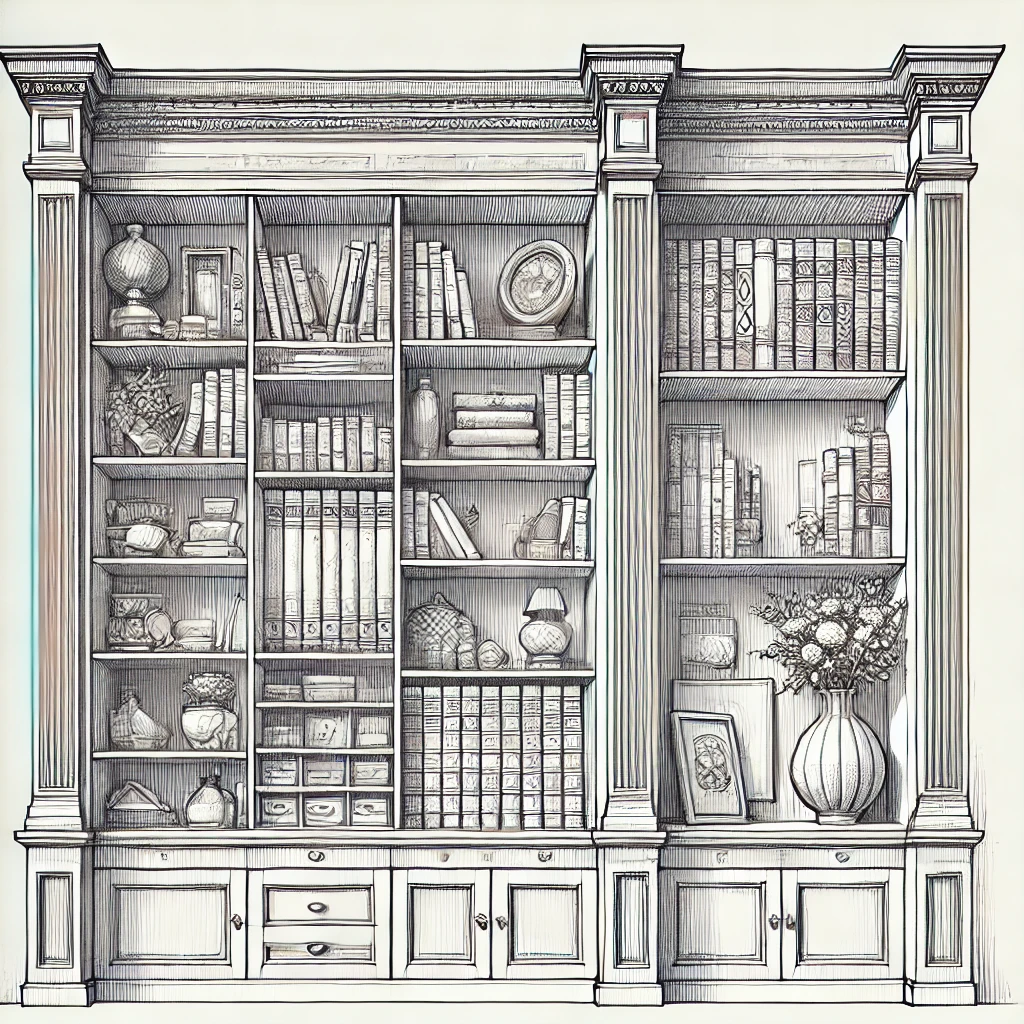

Example 2: Built-In Bookcase for a Home Office

A homeowner needs a built-in bookcase for their home office that provides ample storage and matches the room’s existing Trim. The furniture maker designs a floor-to-Ceiling bookcase using solid oak with adjustable shelves, integrated lighting, and a Ladder rail system. The piece is stained to match the room’s woodwork and installed on-site, transforming the office into a functional and elegant workspace.

Example 3: Upholstered Bench for an Entryway

A couple wants a comfortable seating option for their entryway. The furniture maker designs a custom bench with a tufted leather cushion and a solid wood frame. The wood is stained to complement the home’s flooring, and the leather is selected for durability and easy maintenance. The bench is both stylish and practical, adding seating and storage to the entryway.

Further Reading and Resources

These resources offer further information on working with furniture makers, helping you explore the endless possibilities of custom furniture in your home.

Wrap-Up

By partnering with a skilled furniture maker, you can bring your vision to life with custom pieces that reflect your personality and enhance the functionality of your space. Whether you’re looking for a statement dining table, built-in cabinetry, or a unique upholstered bench, understanding the process and craftsmanship involved will help you achieve a stunning result that is truly one-of-a-kind.