Understanding the Role of Driveway Subcontractors in Home Construction Projects: Types of Driveways, Tools, Materials, Terms, and What to Expect

When planning a home construction project that involves installing or renovating a driveway, hiring specialized driveway subcontractors is essential. These professionals have the expertise, tools, and materials necessary to ensure that your driveway is durable, functional, and visually appealing.

This detailed article will guide you through what to expect when working with driveway subcontractors, the different types of driveways they can install, the tools and materials they use, common terms you’ll hear, and specific examples of their work.

1. Types of Driveways

Driveways come in various materials, each with its own benefits, drawbacks, and installation requirements. Here are some of the most common types of driveways that driveway subcontractors can install:

a. Concrete Driveways

Description: Concrete driveways are popular for their durability and low maintenance. They are made by pouring a concrete mix into a prepared site and then finishing it to create a smooth or textured surface. Concrete driveways can be plain, stamped, colored, or stained to achieve different looks.

Example: A homeowner chooses a Stamped Concrete Driveway to mimic the appearance of Cobblestone, providing a high-end look without the cost of Natural Stone.

b. Asphalt Driveways

Description: Asphalt driveways are made from a mixture of Aggregate (stone, sand, and Gravel) and bitumen (a form of crude oil). They are known for their smooth, black finish and are commonly used due to their affordability and ease of repair. However, they require periodic sealing to maintain their appearance and longevity.

Example: A homeowner installs an Asphalt Driveway for a sleek, professional appearance that complements the modern design of their home. The Subcontractor seals the driveway after installation to protect it from the elements.

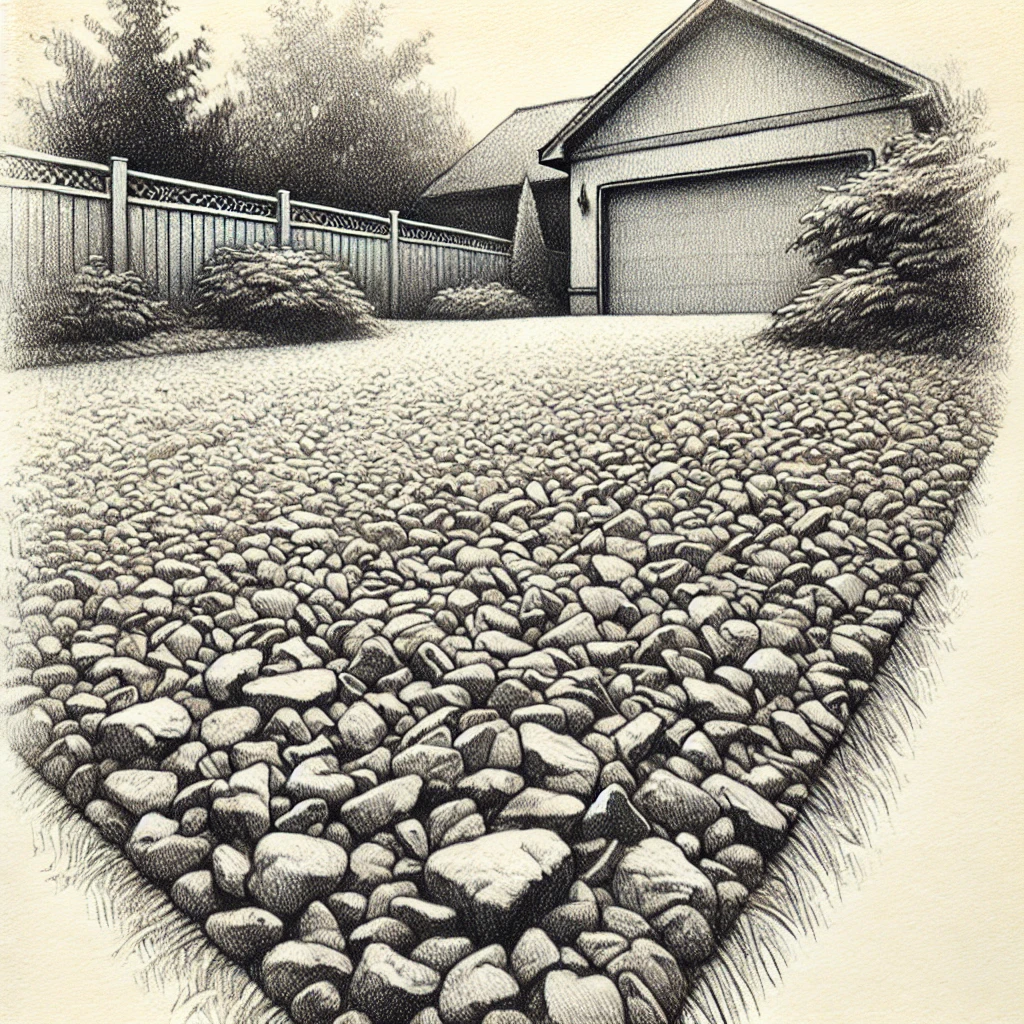

c. Gravel Driveways

Description: Gravel driveways consist of loose stones or gravel spread over a prepared base. They are one of the most affordable driveway options and are easy to install. However, gravel driveways require regular maintenance to keep the surface even and free of ruts.

Example: A rural homeowner installs a gravel driveway to blend with the natural landscape, using large stones for the base layer and smaller gravel for the top layer.

d. Paver Driveways

Description: Paver driveways are made from individual paving stones, such as brick, concrete, or natural stone, laid in a pattern over a prepared base. Paver driveways are highly customizable, offering a wide range of colors, shapes, and patterns. They are durable and can be repaired by replacing individual Pavers.

Example: A homeowner selects a Herringbone pattern with brick pavers for their driveway, creating a classic and timeless look that complements their colonial-style home.

e. Permeable Driveways

Description: Permeable driveways are designed to allow water to drain through the surface, reducing Runoff and helping to manage stormwater. These driveways can be made from permeable pavers, porous concrete, or gravel.

Example: A homeowner concerned about drainage issues installs a permeable paver driveway, which helps prevent flooding by allowing rainwater to filter through the surface and into the ground.

2. Tools and Equipment Used by Driveway Subcontractors

Driveway subcontractors use a variety of specialized tools and equipment to install driveways efficiently and accurately. Here are some of the most common tools and what they’re used for:

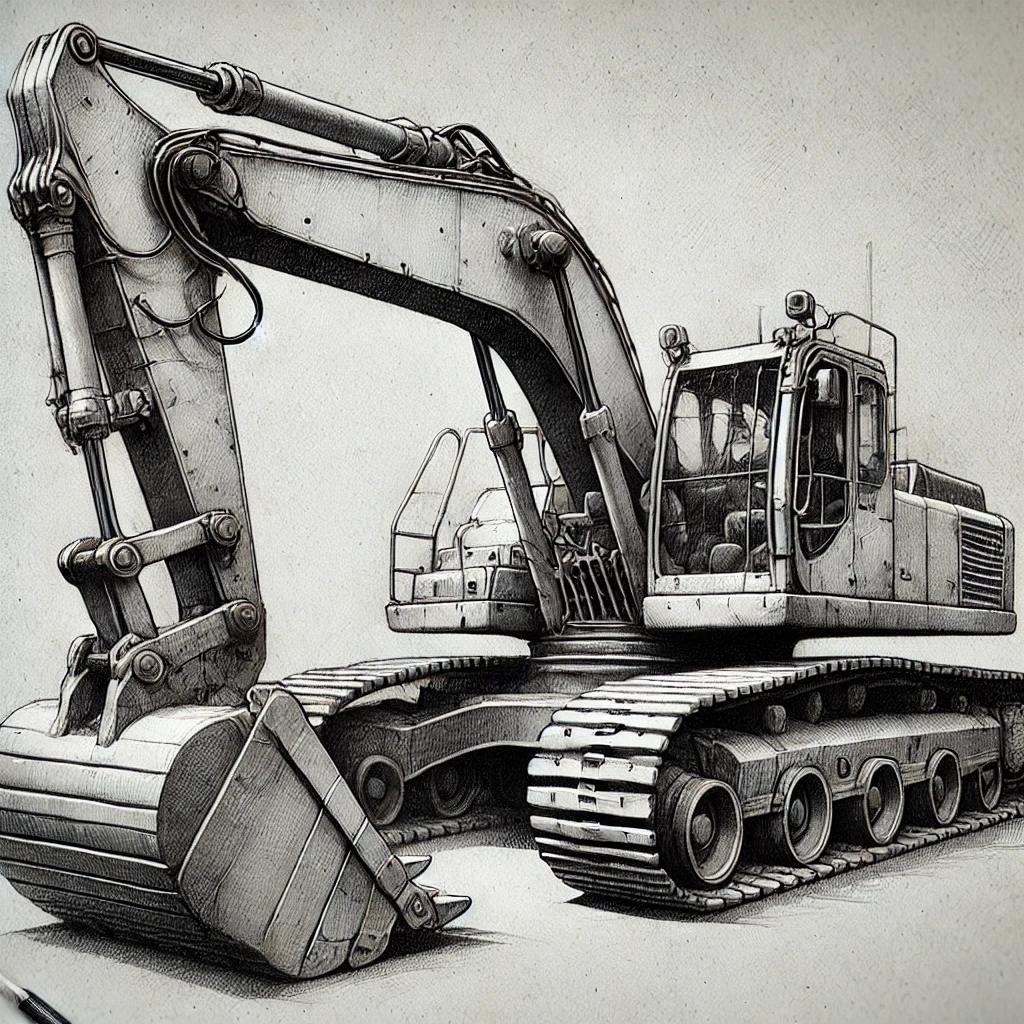

a. Excavators

Purpose: Excavators are used to remove existing driveways, vegetation, and soil to prepare the site for the new driveway. They can dig to the required depth and create a level base for the driveway materials.

Example: Before installing a concrete driveway, the subcontractor uses an Excavator to remove the old asphalt driveway and dig down to the required depth for the new Concrete Slab.

b. Plate Compactors

Purpose: Plate compactors are used to compact the base material (such as gravel or Crushed Stone) to create a stable Foundation for the driveway. Proper Compaction is essential for preventing settling and maintaining the driveway’s structural integrity.

Example: When installing a gravel driveway, the subcontractor uses a Plate Compactor to compress the base layer of crushed stone, ensuring a solid and level surface for the top layer of gravel.

c. Concrete Mixers

Purpose: Concrete mixers are used to mix the ingredients of concrete (Cement, water, sand, and aggregate) to create a uniform and workable mixture. The concrete is then poured and finished to create the driveway surface.

Example: For a new concrete driveway, the subcontractor uses a portable Concrete Mixer to prepare small batches of concrete, allowing for precise control over the mix’s consistency and quality.

d. Asphalt Rollers

Purpose: Asphalt rollers are heavy machines used to compact and smooth the asphalt surface after it has been laid. They help achieve a smooth, even finish and ensure that the asphalt is properly compacted for durability.

Example: After laying the asphalt for a new driveway, the subcontractor uses an asphalt roller to compact the surface, creating a smooth and durable finish.

e. Paver Cutters and Saws

Purpose: Paver cutters and saws are used to cut paving stones to the desired size and shape, allowing them to fit precisely within the driveway’s design. These tools ensure clean, accurate cuts for a professional finish.

Example: When installing a paver driveway in a circular pattern, the subcontractor uses a paver saw to cut the stones to fit perfectly around the edges and curves.

f. Concrete Finishing Tools

Purpose: Concrete finishing tools, such as trowels, floats, and edgers, are used to smooth and finish the surface of poured concrete. These tools help achieve the desired Texture and appearance for the driveway.

Example: After pouring the concrete for a new driveway, the subcontractor uses a bull float to level the surface and an edger to create clean, rounded edges along the driveway’s borders.

3. Materials Used by Driveway Subcontractors

The materials selected for your driveway will significantly impact its durability, appearance, and maintenance requirements. Here are some common materials used by driveway subcontractors:

a. Concrete

Purpose: Concrete is a versatile and durable material that can be used for a variety of driveway designs. It can be poured in different finishes, such as smooth, brushed, or stamped, and can be colored or stained for a customized look.

Example: A homeowner chooses colored concrete for their driveway, adding integral color to the mix to achieve a uniform hue that complements the exterior of their home.

b. Asphalt

Purpose: Asphalt is a cost-effective and easy-to-install material commonly used for driveways. It provides a smooth surface that is resistant to cracking and easy to repair. However, it requires periodic sealing to maintain its appearance and protect it from the elements.

Example: A homeowner installs an asphalt driveway for its affordability and smooth finish, with plans to seal it every few years to extend its lifespan.

c. Gravel

Purpose: Gravel is an affordable and low-maintenance material that provides a rustic and natural look. It is commonly used in rural or country settings and is easy to install. However, it requires regular maintenance to keep the surface even and free of weeds.

Example: A rural homeowner installs a gravel driveway using a mix of large stones for the base layer and smaller gravel for the top layer, creating a durable and attractive surface.

d. Paving Stones (Pavers)

Purpose: Paving stones, such as brick, concrete, or natural stone pavers, are used to create highly customizable and visually appealing driveways. Pavers are durable, easy to repair, and available in a wide range of colors, shapes, and patterns.

Example: A homeowner selects cobblestone pavers for their driveway, creating an elegant and timeless look that enhances the curb appeal of their historic home.

e. Permeable Pavers

Purpose: Permeable pavers are designed to allow water to drain through the surface, reducing runoff and helping to manage stormwater. These pavers are an environmentally friendly option that helps prevent flooding and erosion.

Example: A homeowner installs a permeable paver driveway to address drainage issues on their property, choosing pavers that match the aesthetic of their home while improving stormwater management.

4. Common Terms Used by Driveway Subcontractors

Understanding the terminology used by driveway subcontractors can help you communicate more effectively and make informed decisions. Here are some common terms you’ll hear:

a. Base

Definition: The base is the layer of material (usually gravel or crushed stone) that is placed beneath the driveway surface. The base provides stability, drainage, and support for the driveway.

Example: The subcontractor installs a 4-inch layer of crushed stone as the base for a new concrete driveway, ensuring proper drainage and a solid foundation.

b. Curing

Definition: Curing refers to the process of maintaining the proper moisture and temperature conditions for concrete or asphalt to achieve its full strength. Proper curing is essential for the durability of the driveway.

Example: After pouring a concrete driveway, the subcontractor covers it with plastic sheeting to retain moisture and control the curing process, preventing cracks and ensuring a strong surface.

c. Expansion Joints

Definition: Expansion joints are intentional gaps or cuts in concrete driveways that allow for the expansion and contraction of the material due to temperature changes. These joints help prevent cracking.

Example: The subcontractor installs expansion joints at regular intervals across the concrete driveway to accommodate movement and prevent unsightly cracks.

d. Overlay

Definition: An overlay is a layer of material, such as asphalt or concrete, applied over an existing driveway surface to restore its appearance and improve its durability. Overlays are often used as a cost-effective way to extend the life of a driveway.

Example: A homeowner with an aging asphalt driveway opts for an asphalt overlay, which the subcontractor applies to restore the driveway’s smooth finish and extend its lifespan.

e. Sealcoating

Definition: Sealcoating is the application of a protective coating to an asphalt driveway to protect it from the elements, prevent oxidation, and extend its lifespan. Sealcoating also enhances the appearance of the driveway by restoring its black color.

Example: After installing an asphalt driveway, the subcontractor recommends applying sealcoat every 2-3 years to protect the surface and maintain its appearance.

f. Resin-Bound Driveway

Definition: A resin-bound driveway is created by mixing aggregate (stone) with resin and then laying it over a prepared surface. This type of driveway is permeable, durable, and available in various colors and textures.

Example: A homeowner chooses a resin-bound driveway with a blend of natural stone colors to create a unique and attractive surface that complements the landscaping.

5. What to Expect When Working with Driveway Subcontractors

When you hire driveway subcontractors for your home construction project, you can expect a process that involves careful planning, precise execution, and attention to detail. Here’s what you should anticipate:

a. Initial Consultation and Design

The process typically begins with an initial consultation where the subcontractor will discuss your project, assess the site, and provide recommendations. They will help you choose the best type of driveway, design, and materials based on your needs, preferences, and budget.

Example: If you’re considering a new paver driveway, the subcontractor will assess your driveway’s layout, recommend different paver materials and patterns, and provide a detailed cost Estimate.

b. Site Preparation

Before any installation begins, the site must be prepared. This includes removing any existing driveway, clearing vegetation, and Leveling the ground. The subcontractor will also install the base material, which is crucial for the driveway’s durability.

Example: For a new asphalt driveway, the subcontractor removes the old concrete driveway, excavates the site to the required depth, and installs a compacted gravel base to provide a stable foundation.

c. Material Installation

Once the site is prepared, the subcontractor will install the chosen materials, whether it’s concrete, asphalt, gravel, or pavers. This involves laying the materials, ensuring proper alignment, and finishing the surface according to the design.

Example: During the installation of a concrete driveway, the subcontractor pours the concrete, smooths the surface with a trowel, and applies a broom finish for added texture and slip resistance.

d. Curing and Sealing

After the materials are installed, the driveway must be cured (for concrete or asphalt) or sealed (for asphalt) to ensure it reaches its full strength and durability. Proper curing and sealing are essential for preventing cracks, water damage, and other issues.

Example: After installing a concrete driveway, the subcontractor covers it with plastic sheeting to retain moisture during curing. Once cured, they apply a Sealant to protect the surface from stains and water damage.

e. Final Inspection and Clean-Up

Once the driveway is complete, the subcontractor will conduct a final inspection to ensure that the work meets all Specifications and quality standards. They will also clean up the site, removing any debris or leftover materials.

Example: After completing a paver driveway, the subcontractor inspects the entire surface to ensure all pavers are properly aligned and compacted. They then clean up any excess sand or debris, leaving the driveway ready for use.

6. Further Reading and Resources

For more information on working with driveway subcontractors and understanding their role in construction projects, consider visiting the following resources:

National Asphalt Pavement Association (NAPA): NAPA Website

Concrete Network: Concrete Network Website

Interlocking Concrete Pavement Institute (ICPI): ICPI Website

Fine Homebuilding - Driveway Materials and Design: Fine Homebuilding

These resources can provide additional insights and help you make informed decisions when working with driveway subcontractors on your home construction project.

Wrap-Up

Driveway subcontractors play a crucial role in enhancing the functionality, durability, and aesthetics of your home’s exterior. By understanding the different types of driveways available, the tools and materials they use, the common terms you’ll hear, and what to expect during the process, you can ensure that your driveway project runs smoothly and meets your expectations.

Whether you’re installing a new concrete driveway, upgrading to pavers, or repairing an existing asphalt surface, working with skilled subcontractors is key to achieving a high-quality result that adds value to your home.